Prop building season is upon us again.

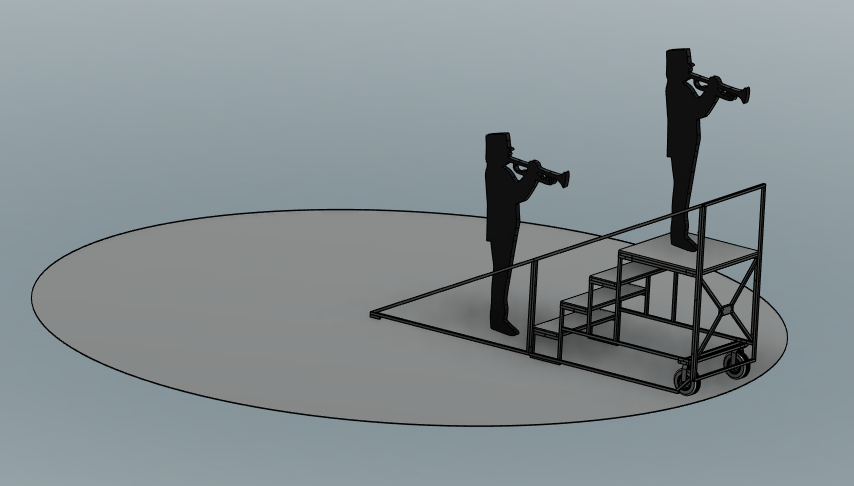

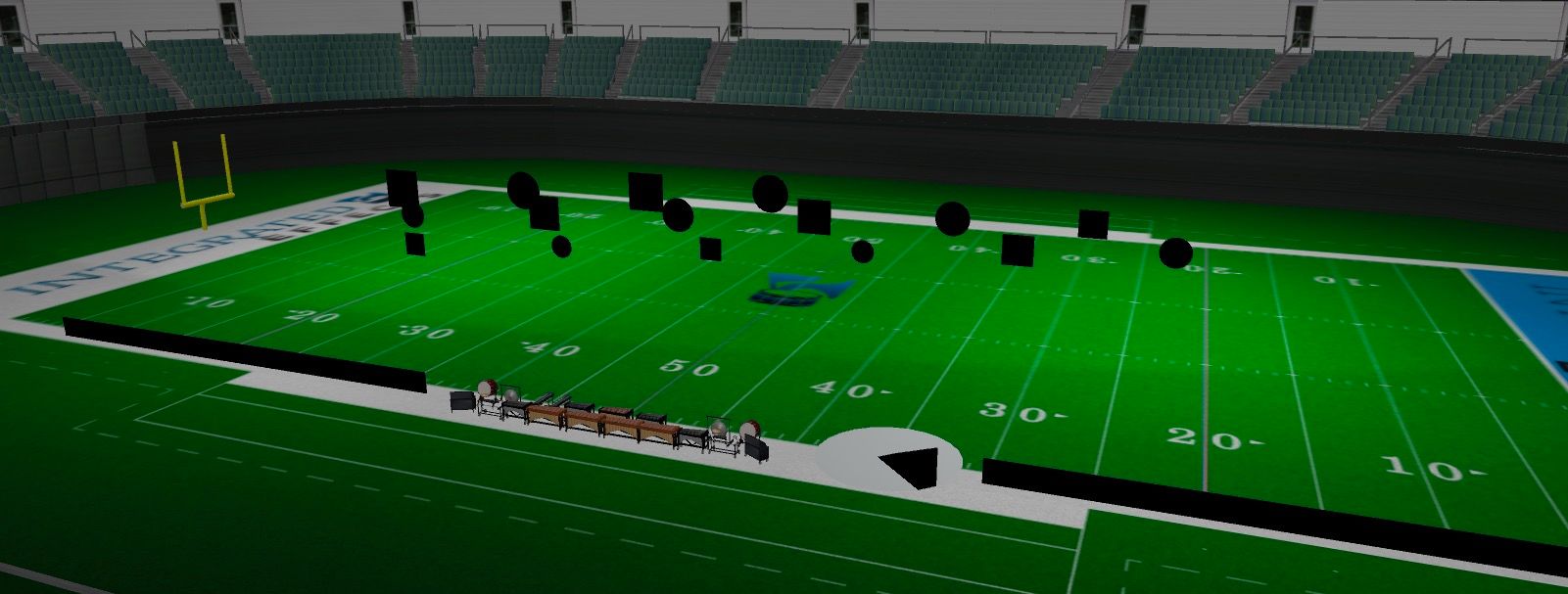

The 2024 Marching Show was revealed in April. This year's show is titled "It's About Time." The show will feature a graveyard of timepieces. Imagine clocks, hourglasses, pocket watches, watch gears as if they were half buried by the field. The solo stage will be a sundial by which soloists could ascend to perform or stage features below.

Concept Drawings

I received a sketch outlining this year's props. We plan to use Coroplast printing to create a set

design resembling a graveyard of timepieces.

The design features 16 timepieces, varying in size from 6x6 feet to 12x12 feet, depicted as circles

and squares in the concept drawing. Adjacent to

the front ensemble, there will be a 22-foot sundial, with the gnomon (also known as the pointer or

style) serving as a stage for soloists to ascend

and perform or to feature elements below. Additionally, there will be 180 feet of front drops, also

known as sideline screens, with 90 feet flanking

each side of the front ensemble.

I received a sketch outlining this year's props. We plan to use Coroplast printing to create a set

design resembling a graveyard of timepieces.

The design features 16 timepieces, varying in size from 6x6 feet to 12x12 feet, depicted as circles

and squares in the concept drawing. Adjacent to

the front ensemble, there will be a 22-foot sundial, with the gnomon (also known as the pointer or

style) serving as a stage for soloists to ascend

and perform or to feature elements below. Additionally, there will be 180 feet of front drops, also

known as sideline screens, with 90 feet flanking

each side of the front ensemble.

And here are the final props on the field during our contest.

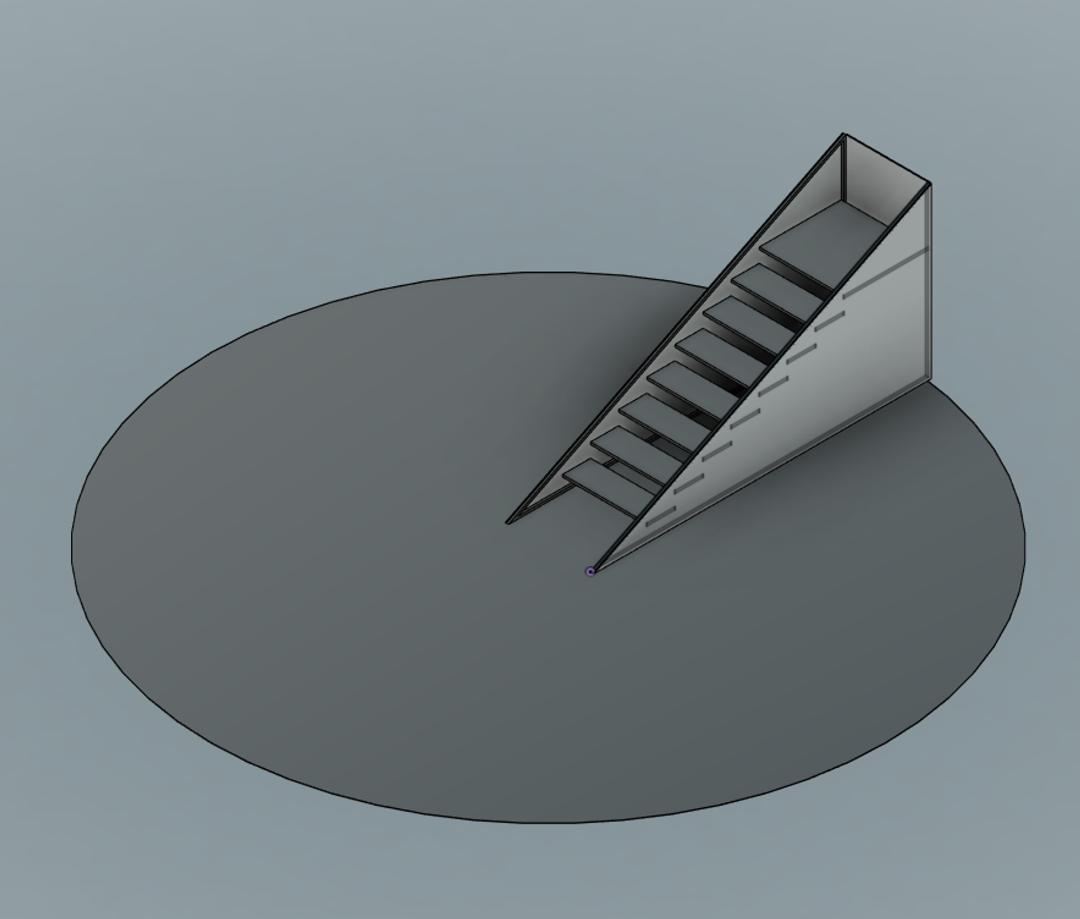

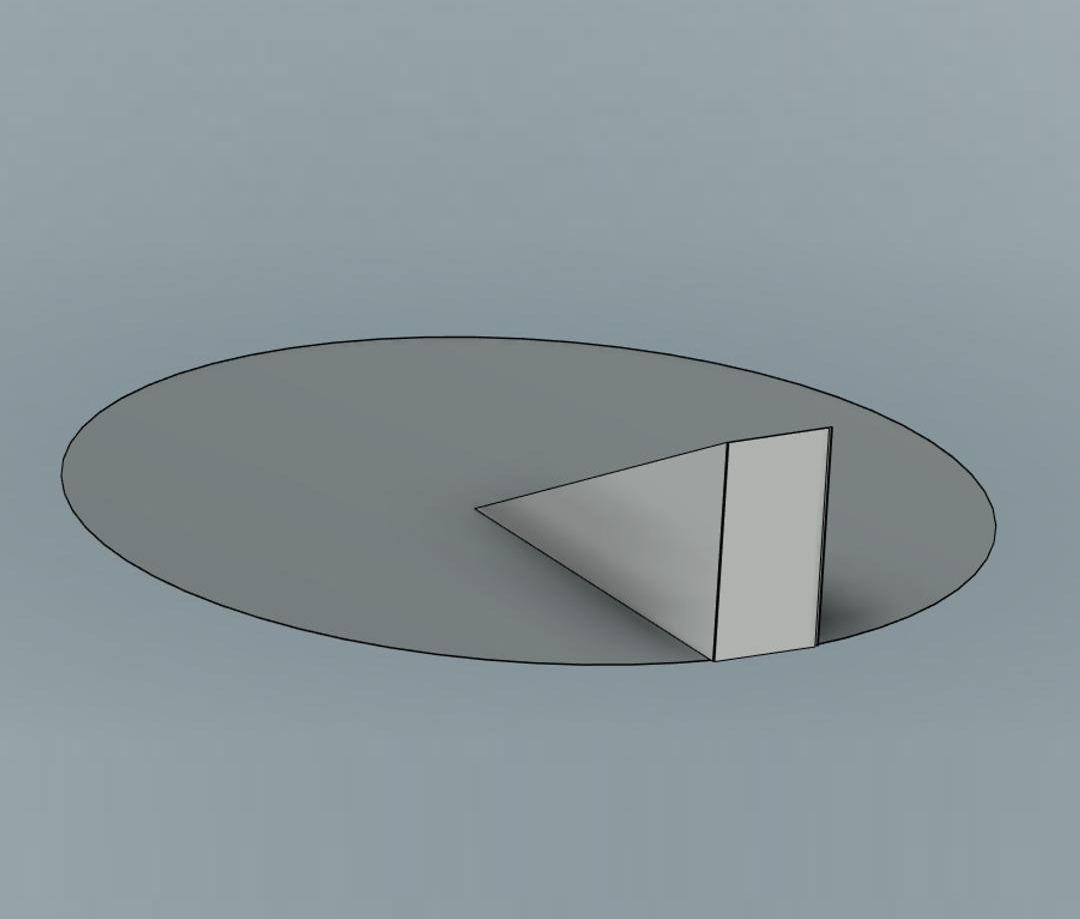

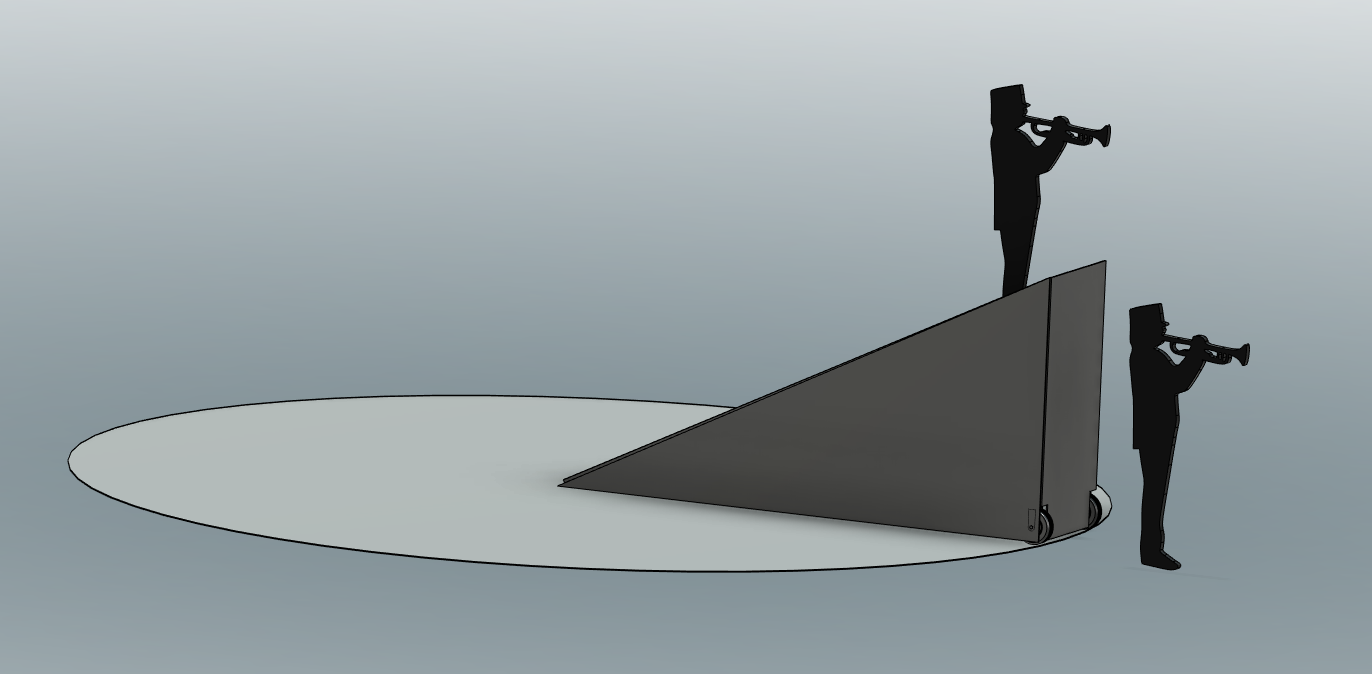

Sundial

My first focus was to design the stage for the sundial. The ground tarp would be ordered, so no work was needed from me there. The parameters I received for the sundial were that the pointer should be 12 feet in length (from the center of the dial), 3 feet wide, and should raise to a height of 6 feet from the floor. Inside, there would be a set of stairs ascending to a 3x3 platform, 4 feet off the ground. Additionally, I aimed to design the stage to be disassembled for more compact travel in the trailer, with the goal, as in previous years, of fitting all the props into our 20-foot band trailer and avoiding the need to rent a box truck for transport.

I started with a quick mockup in Fusion 360 to get a feel for the sundial's design and to make sure it meets the expectations of the show designer. My first design had steps leading to the platform have a 6-inch rise with a 12-inch run.

After I sent this mockup for feedback, I looked at other prop designs online and noticed that 1-foot-high steps were common. So, I asked the show designer if there was a preference between fewer but taller steps or more but shorter steps. The feedback was, '1-foot steps don't pose much of an issue because that's what we are used to. Any bigger, and it gets awkward.' This led to mockups with three steps leading to the platform with wheels. The steps are 1 foot high, shown with and without the plastic sides, with trumpet players included for scale. I believe opting for three steps instead of seven will make this prop easier to move and build.

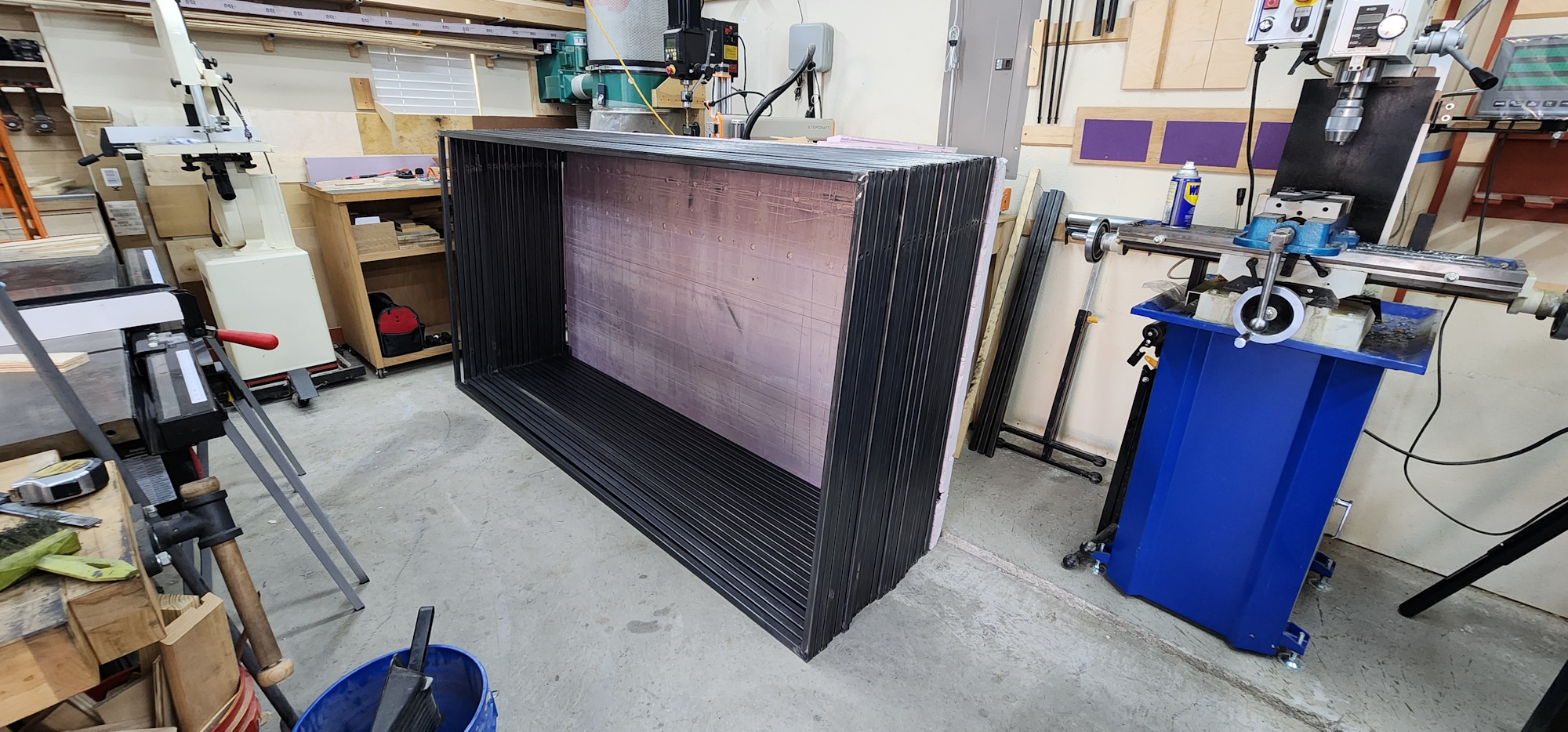

And here is the built stage and ground tarp.

And a time lapse of building the stage.

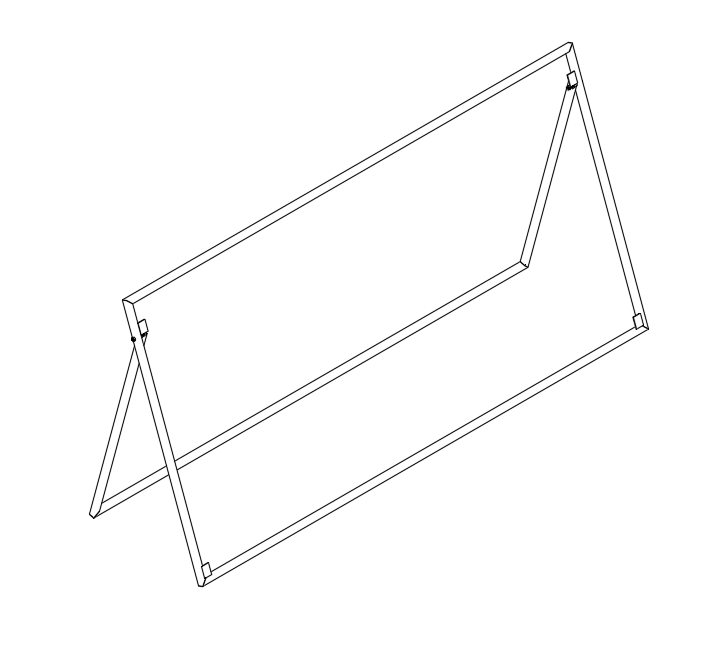

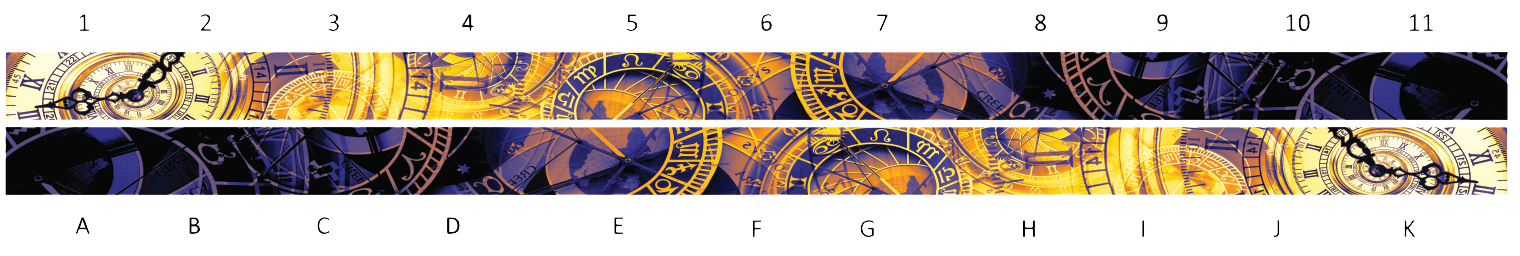

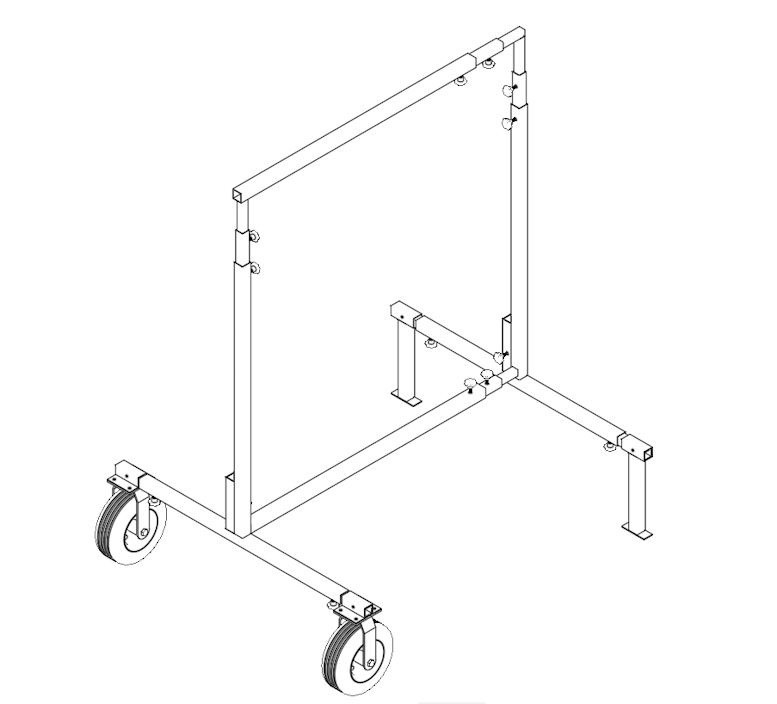

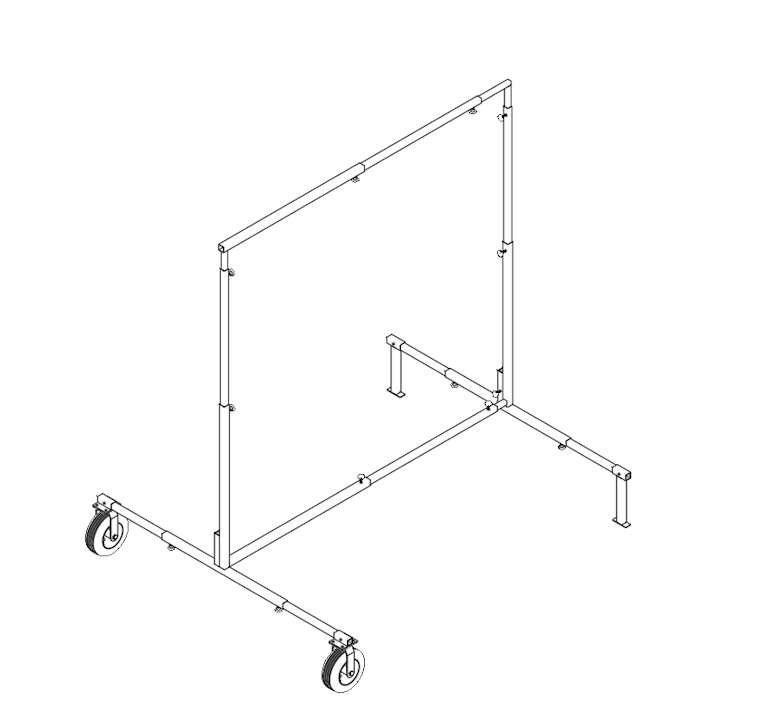

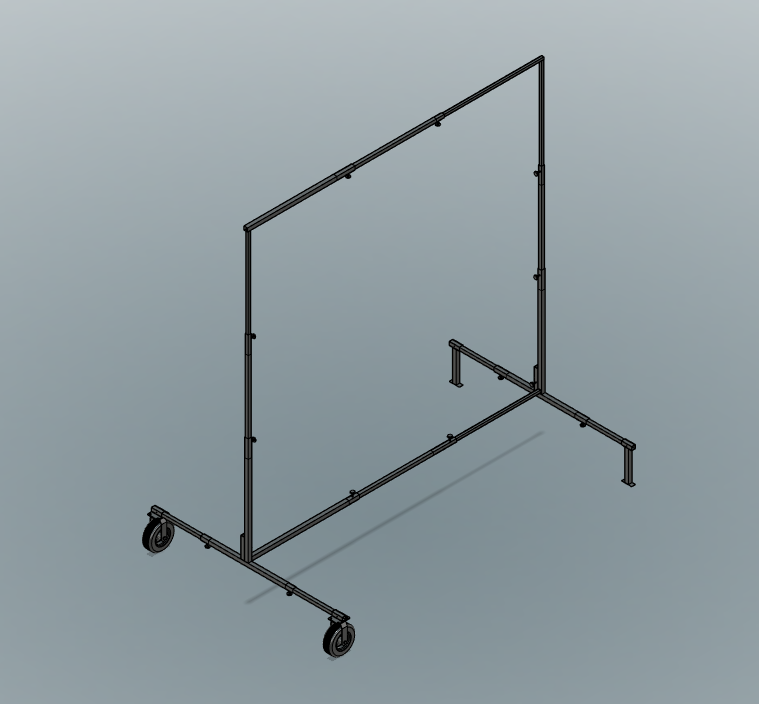

Sideline Screens

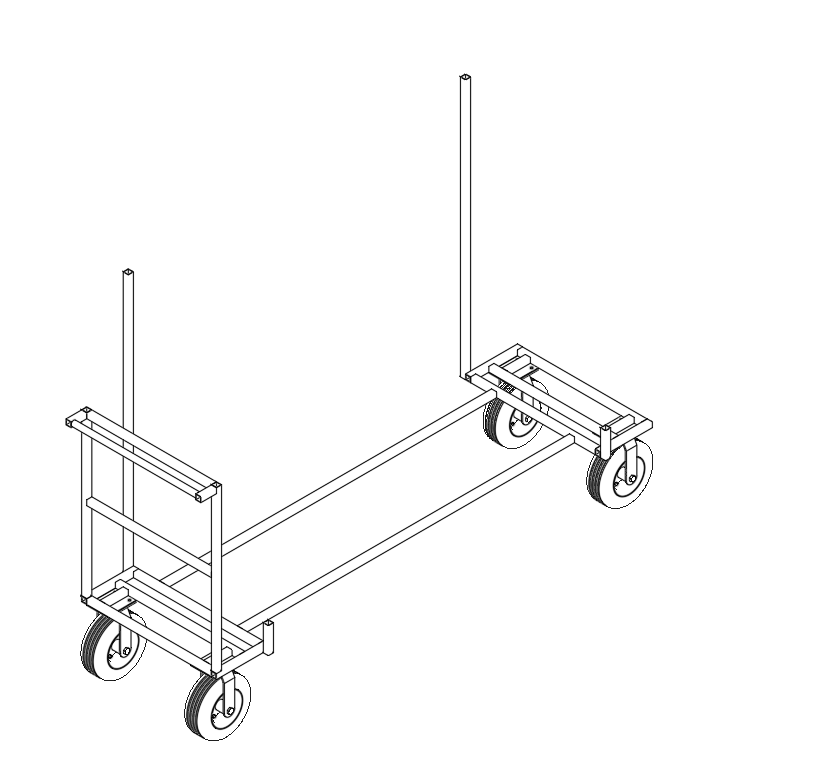

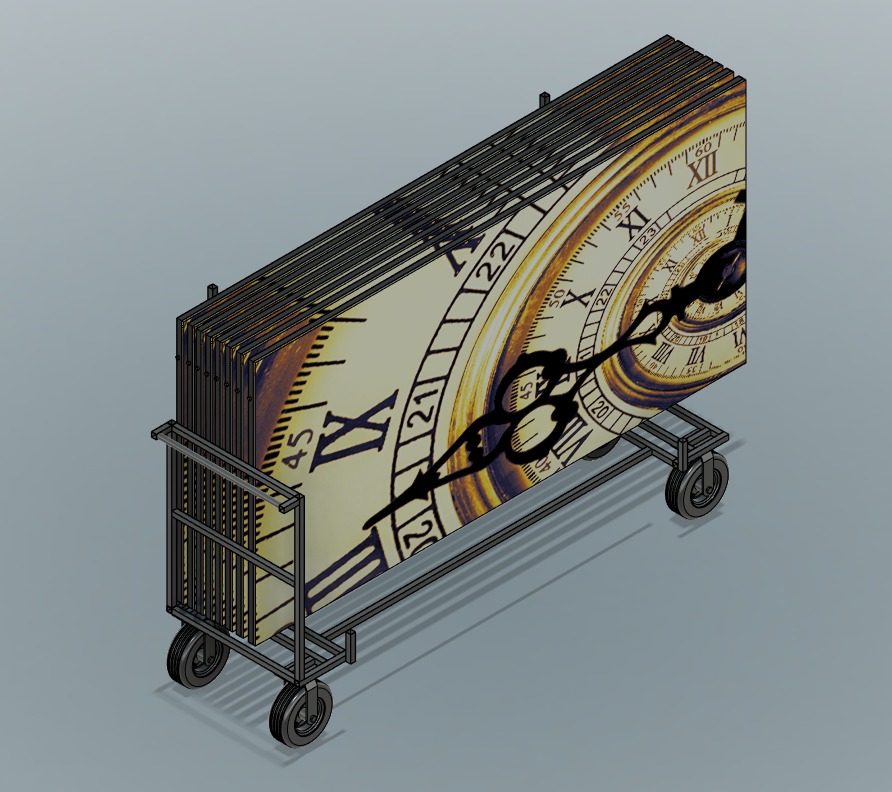

My goal has been to replace these PVC frames with metal frames featuring kickstand-style legs that fold into the frame. I've seen other schools use these, and they appear to be much easier to set up and move around. It's also part of the plan to build dedicated carts for transporting the sideline screens. We'll use 4x8 sheets of 4mm Coroplast for the sideline screen artwork. Given these dimensions, it made sense to build the frames to match the 4x8 size. Building 22 screens will provide 88 feet of coverage on each side of the front ensemble. Additional design considerations include ensuring that the legs have a stop when opened, allowing quick and uniform setup for all the screens. I wanted a design with no loose parts and no assembly required. I had seen a few similar designs online retailing for around $300 each. However, I can source the metal for about $50 per screen — and band dad labor is free! There will also be a few nuts, bolts, and some spray paint needed to complete them. The carts will cost about $100 in metal, and we plan to reuse wheels from a previous year's prop build. We are building two carts; while all 22 screens could fit on a single cart, that much weight would be too heavy to manage safely.

The Right and Left sideline screen setup. We numbered the right and lettered the left to help with setup.

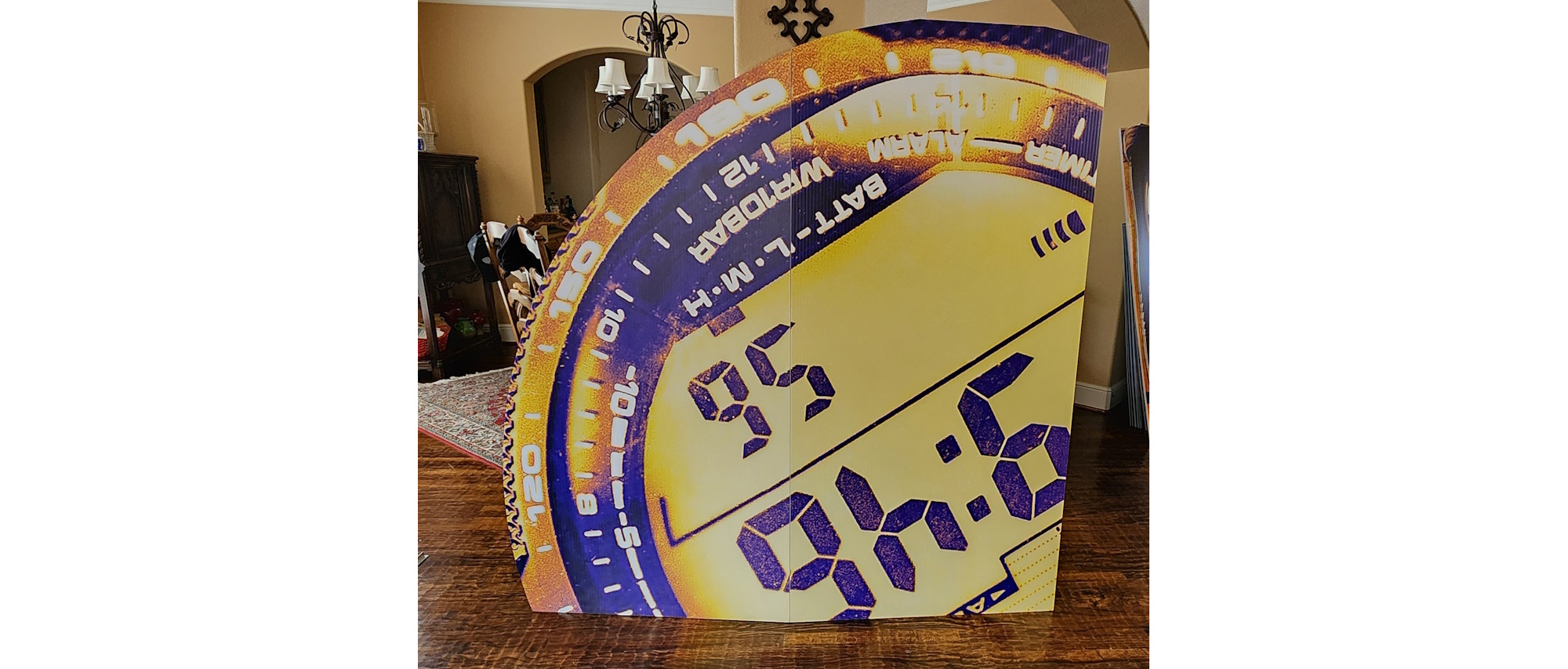

And actual screens.

Carts in action!

Back Props

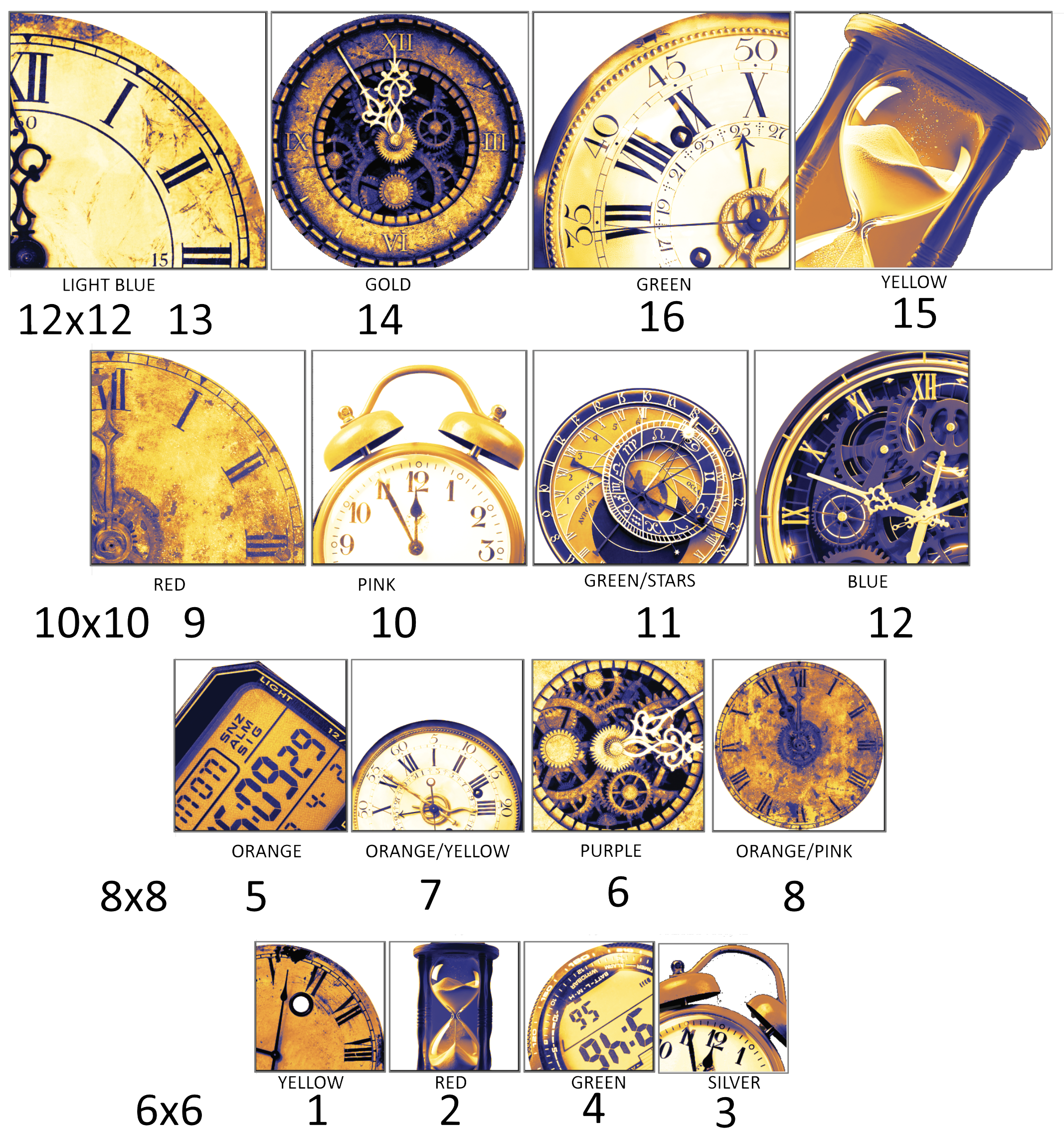

There will be a total of 16 back props, each coroplast-printed with different timepieces:

- 4 extra-large (12x12)

- 4 large (10x10)

- 4 medium (8x8)

- 4 small (6x6)

Each prop was assigned a spot number and color-coded to its frame to make assembly easier and faster.

To support the back props we are building Expandable Media Frames that expand from 4x4 feet to 10x10 feet.

However, we abandoned this idea after building a prototype frame and not being satisfied with how it turned out. Expanding and contracting the frame was not easy, and it seemed more practical to build fixed-size frames instead. So, that is what we did. We built seven fixed-size media frames with wheels and nine fixed frames out of EMT that sit on the ground.

Here are a few of the coroplast printed timepieces.

Progress Blog

Sunday, October 6, 2024

Thursday, October 3, 2024

Sunday, September 29, 2024

Saturday, September 28, 2024

Thursday, September 26, 2024

Tuesday, September 24, 2024

Monday, September 23, 2024

Sunday, September 22, 2024

blog post to come

In morning (before work session)

cut EMT, drilled EMT, drilled holes for wheel plate parts

During work session, finished media frame (drill holes in long pieces, painted all metal,

attached wheel )

Saturday, September 21, 2024

blog post to come

Home Depot to buy paint and

acetone

prepared "to-do" for Sunday's work session

Friday, September 20, 2024

Thursday, September 19, 2024

blog post to come

I chose to avoid a sweaty night

and worked through designs for the 12x12 EMT frames, ordering bolts and pins from

McMaster-Carr.

Wednesday, September 18, 2024

Tuesday, September 17, 2024

Monday, September 16, 2024

Sunday, September 15, 2024

Saturday, September 14, 2024

Friday, September 13, 2024

Thursday, September 12, 2024

Sunday, September 8, 2024

Saturday, September 7, 2024

Wednesday, September 4, 2024

Tuesday, September 3, 2024

Monday, September 2, 2024

blog post to come

We taped 6x6 coroplast together;

layout out prop paper cuts to figure out a plan for their frames;

Built EMT frame for 8x8 prop and mounted it;

Welded bolts to washers and then washers to EMT. This worked, but wasn't great;

Started welding front screen carts.

Sunday, September 1, 2024

blog post to come

Prep metal for front screen carts

Saturday, August 31, 2024

blog post to come

Built prototype expandable media

frame

Sunday, August 25, 2024

blog post to come

finished welding all 22 front

screens

Saturday, August 24, 2024

blog post to come

welded screens and took stage to

band practice for directors to see and use

Friday, August 23, 2024

blog post to come

CAD work on media frames and

screen cart

Thursday, August 22, 2024

Painted stage metal

Wednesday, August 21, 2024

blog post to come

setup gas for welding. Welded

braces and feet for stage

Wednesday, August 21, 2024

Tuesday, August 20, 2024

Sunday, August 18, 2024

Friday, August 16, 2024

blog post to come

CAD work on back props

Monday, August 12, 2024

blog post to come

Built a second screen frame to

test leg angle, cut 45s on all the 48" pieces

Sunday, August 11, 2024

Saturday, August 10, 2024

Friday, August 9, 2024

Thursday, August 8, 2024

August 5, 2024

blog post to come

Placed metal order for front

screens and stage

August 4, 2024

blog post to come

More CAD work on Stage and

generated Drawings for Front Screens

August 3, 2024

blog post to come

More CAD work on Stage

July 30, 2024

blog post to come

Printed art work and stitched

together back props

July 23, 2024

blog post to come

More CAD work on front screens

July 20, 2024

blog post to come

CAD work on front screens

July 15, 2024

blog post to come

CAD work on Stage

July 14, 2024

blog post to come

CAD work on Stage and front

screens

July 5, 2024

blog post to come

CAD work on back props frame

April 30, 2024

blog post to come

First meeting with Reid

Budget and Materials

The prop budget for this year was $10,000, with actual expenses totaling $9,581.45. The table below provides a detailed breakdown of the expenses. To minimize costs, we repurposed 10-inch wheels from last year's props. This expenses also included building 22 sideline screen frames with two carts for transporting them. And 7 media frames for the back props. All of which will be reused in future years.| Date | Store | Cost | Details |

|---|---|---|---|

| 7/29/2024 | Flash Visual Media | $5,054.80 |

Coroplast & Vinyl Graphics Floor Props or Small Tarps: 22'6" x 22'6" - 13 oz - Customprinted (Qty 1) - $506.25 10 mm - Single-Sided - Complex Cuts (49) - $3,737.23 4 mm - Single-Sided - Straight Lines only (22) - $661.32 Art Package - $150.00 |

| 8/5/2024 | Metal Store | $1,360.84 | Sideline Screens & Stage metal |

| 8/10/2024 | Home Depot | $21.96 | Acetone x 2 |

| 8/21/2024 | Amazon | $11.90 | 60Pcs M8 x 30 Hex Hand Star Knobs |

| 8/21/2024 | PrimeWeld | $85.84 | welding gas |

| 8/21/2024 | Home Depot | $134.86 | Paint, Acetone, Welding wire |

| 8/23/2024 | McMaster-Carr | $35.43 | Nuts, Sq Plugs for Tubing |

| 8/26/2024 | Metal Store | $412.62 | parts for 2 screen carts, 1 media frame |

| 8/27/2024 | Flash Visual Media | $330.80 | Vinyl for stage |

| 8/24/2024 | Home Depot | $14.03 | Paint |

| 9/1/2024 | Amazon | $12.55 | 50 wing nuts |

| 9/1/2024 | Home Depot | $204.84 | EMT, Paint, U-Bolts, Eye Bolts |

| 9/2/2024 | Amazon | $34.18 | Lock nuts, washers, Nut spacers |

| 9/2/2024 | McMaster-Carr | $48.47 | 25 Tube Connecting Nuts |

| 9/2/2024 | McMaster-Carr | $28.63 | 50 3" hex screws |

| 9/4/2024 | Metal Store | $597.15 | Metal for back prop media frames |

| 9/6/2024 | Home Depot | $161.40 | 30 x EMT |

| 9/7/2024 | Amazon | $26.27 | T-Nuts, 3/8 Nuts for spacers |

| 9/15/2024 | Home Depot | $184.54 | 20 x EMT, Gorilla Tape, Welding wire |

| 9/18/2024 | Metal Store | $349.15 | 24 long pieces for media frames |

| 9/19/2024 | McMaster-Carr | $178.42 | bolts, wing nuts, washers, ubolts, pins |

| 9/12/2024 | Home Depot | $70.78 | 10x Paint, Acetone |

| 9/21/2024 | Amazon | $32.40 | gorilla tape - 3 rolls clear |

| 9/22/2024 | Home Depot | 23.77 | Acetone x 2 |

| 9/22/2024 | Home Depot | 38.84 | Paint x 6 |

| 9/22/2024 | Home Depot | 5.63 | Hex bolts for wheels |

| 9/23/2024 | Home Depot | $48.17 | e-track board holders x 4 |

| 10/2/2024 | Amazon | $35.98 | magnets / bungee cords |

| 10/2/2024 | Home Depot | $37.20 | EMT, 2x4 boards, paracord, expoxy |